|

Update on viewpoints in the CNC tool industry

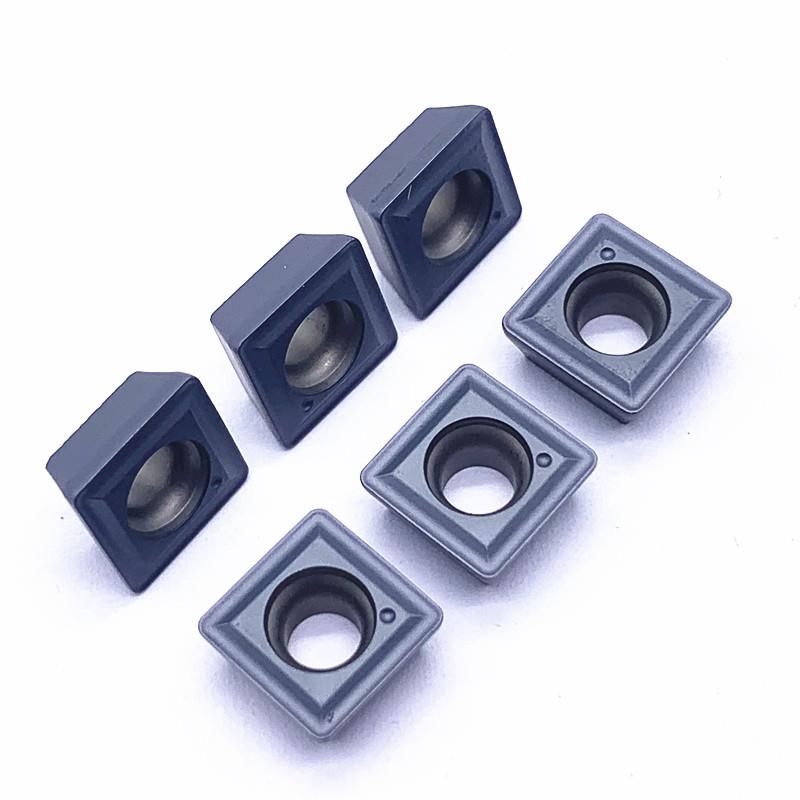

The CNC cutting tool industry chain can be divided into upstream raw materials, midstream tool manufacturers, and downstream application industries. The main raw materials for CNC cutting tools are carbonized hook powder and cobalt powder, so the upstream of the industrial chain are enterprises that produce raw materials, such as Xiamen Hook Industry, Luoyang Muye, etc; The enterprises in the midstream that produce CNC cutting tool blades mainly include Xiamen Hook Industry, Zhongtungsten High tech, Oukeyi, Huarui Precision, etc; Downstream application industries are wide, ranging from general machinery, automobiles and motorcycles, building energy, to high-end aerospace, military industry and other fields. 1.1 Definition of Machine Tool Tools Machine tool: refers to the machine used to manufacture machines, also known as industrial mother machines; The cutting tools discussed in this article are key components of metal cutting machine tools. Machine tool: Refers to the tool used for cutting in mechanical manufacturing, also known as cutting tool. Structurally, the overall cutting tool generally consists of a tool holder (connecting the machine spindle and the cutting tool) and a blade, while the blade of the indexable tool can be replaced independently. Among them, the blade is a key executive component that plays a cutting role in metal processing. 1.2 Market size of the cutting tool industry The market size of cutting tools in China experienced rapid growth from 2016 to 2018, with a total tool consumption of 42.1 billion yuan in 2018, exceeding the high of 40 billion yuan in 2011 and setting a historical record. In 2019, downstream manufacturing industries such as automobiles experienced a downturn, coupled with intensified trade frictions between China and the United States, resulting in a slight decline in China's tool consumption to 39.3 billion yuan. After the COVID-19 pandemic in 2020, China's economy rapidly recovered, and the annual consumption of the cutting tool industry once again reached a new high, reaching 42.1 billion yuan. In 2021, the market size further increased to 47.7 billion yuan. According to QY Research data, the global consumption of cutting tools reached 37 billion US dollars in 2020. It is predicted that the global consumption of cutting tools will reach 39 billion US dollars in 2022, with a compound growth rate of 2.82% from 2016 to 2020. The market space for CNC blades mainly depends on the quantity and capacity utilization of CNC metal cutting machine tools in China, as well as the prosperity of downstream manufacturing industry; The future increment is influenced by various factors, such as manufacturing upgrading, increased CNC rate, import substitution, and overseas expansion. 1.3 Splitting of Tool Categories The cutting tools used for metal cutting machine tools are mainly divided into high-speed steel, hard alloys, ceramics, and superhard materials according to the hardness of the materials from low to high. According to data from the China Machine Tool Industry Association, the market size of metal cutting machine tools in China was approximately 47.7 billion yuan in 2021, of which hard alloys accounted for about 51%, reaching 24.327 billion yuan; According to the statistics of the China Machine Tool Industry Association, blades account for about 54% of the sales revenue of hard alloy cutting tools for member enterprises. Based on this, it is estimated that the domestic market size of hard alloy cutting tools is around 13.14 billion yuan. Hard alloy CNC cutting tools can be roughly divided into integral hard alloy cutting tools and detachable/indexable cutting tools according to their structure. Among them, the use of indexable cutting tools is more convenient, and the blade can be directly disassembled and replaced after reaching its service life. Blades can be divided into turning, ironing, and drilling blades according to the processing method, with turning blades accounting for the largest proportion. After hundreds of years of development history, cutting tools have formed a consumption structure mainly composed of hard alloys, with various materials such as high-speed steel and superhard materials (ceramics, diamonds, etc.) coexisting. The mainstream products are high-speed steel cutting tools and hard alloy cutting tools, with their output value accounting for over 90%. From 2015 to 2019, the proportion of output value of hard alloy cutting tools in China has been increasing year by year, and it is expected to reach 53% by 2020. According to a forward-looking information report, hard alloy cutting tools dominate the world, accounting for 63%. In terms of processing performance, superhard material cutting tools have an absolute advantage, with the fastest processing speed; In terms of price, the unit price of ultra hard blades is around 70 yuan, while the average price of hard alloy blades is 6-7 yuan per piece; In terms of market, hard alloy cutting tools and high-speed steel cutting tools have a wide range of applications and a large market, while superhard cutting tools are generally used for high-end precision machining, such as in the aerospace field, and the market is relatively small. 2.1 Benefit 1: Downstream manufacturing investment drives the development of the cutting tool industry Downstream manufacturing investment brings incremental benefits to the tool industry, but due to limited production capacity, the main logic of industry development is still the demand for import substitution in the stock market. Since February 2020, the manufacturing industry has rebounded, and the PMI has remained above the 50% boom bust line. At the same time, leading enterprises in the domestic tool industry, including Zhuzhou Diamond, OKE, and Huarui Precision, are rapidly expanding their production. Although the cumulative value of fixed asset completion in the manufacturing industry has not returned to the level before the 2019 epidemic this year, there is strong demand for cutting tools, and several leading enterprises have accumulated orders for 2-4 months of production capacity. It can be seen that when the macro-economy is in an upward cycle, the demand for fixed assets investment increases, which has a strong pulling effect on the downstream industry, thus driving the rapid development of the cutting tool industry; But when economic expansion slows down and manufacturing investment decreases, the tool industry still has demand in the stock market. 2.2. Advantage 2: Manufacturing Upgrade, Unlimited Potential in Blade Industry Benefiting from a series of industrial policies issued by the country and industry associations, China's cutting tool industry is expected to maintain a high level of prosperity. As a core component of metal cutting machine tools, the cutting tool industry also benefits from the favorable policies introduced by the country for the machine tool industry. The National Development and Reform Commission has repeatedly mentioned in its plan to promote the innovative development of high-end CNC machine tools and high-performance cutting tools, and has classified the manufacturing of hard alloys and products as a strategic emerging industry, which will continue to lead the development of the domestic CNC tool industry. 2.3. Advantage 3: Domestic blade technology upgrade, accelerated import substitution China is currently in the stage of adjusting and upgrading its industrial structure, and there is significant room for improvement in the proportion of tool consumption. Under the trend of Industry 4.0, the manufacturing industry is actively seeking transformation and upgrading to make up for its shortcomings. Modern cutting processing also requires higher requirements for tool stability, machining accuracy, feed rate, and service life. In the consumption structure of tool products in machine tools in China, the proportion of CNC blades in machine tool consumption has increased from 14.1% in 2012 to 32.1% in 2020, indicating that China's tool consumption is improving and upgrading, but there is still a certain gap from being a strong traditional manufacturing country; According to the prospectus of Huarui Precision Convertible Bond, manufacturing powers such as Germany, the United States, and Japan focus on the coordinated and balanced development of CNC machine tools and efficient cutting tools, with an annual consumption scale of about 50% of machine tool consumption. With the gradual shift of domestic end-users' production concepts from relying on cheap labor to improving processing methods and improving efficiency, as well as the transformation and upgrading of the manufacturing industry, there is still significant room for improvement in the scale of tool consumption in China. The epidemic is just the trigger, and since 2017, the domestic market share of imported cutting tools has shown a downward trend. Due to the impact of the epidemic in the past two years, foreign tool manufacturers have experienced delayed supply and logistics delays, providing domestic enterprises with opportunities for import substitution. In the past 30 years, with the emergence of emerging enterprises in the domestic tool industry, various enterprises have increased their R&D investment, combined with subsidies and tax reduction policies for specialized, refined, and new enterprises. The advantages of tool technology upgrading and local services have emerged, and the process of domestic substitution has been accelerating. The market share of imported tools has gradually decreased from 37.2% in 2016 to 34.6% in 2019. 2.4. Benefit 4: The increase in CNC rate brings incremental benefits to CNC cutting tools Numerical control of machine tools is an upgrading trend in the machine tool industry. While reducing costs and increasing efficiency, the increase in numerical control rate also brings increment to the CNC tool market. In recent years, the CNC rate of machine tools in China has maintained stable growth. In 2020, the proportion of metal cutting CNC machine tool production reached 43.2%, a year-on-year increase of 23.3%. According to the "Made in China 2025" plan of the State Council, it is expected that by 2025, the popularization rate of digital research and development design tools in China will reach 72%, and the CNC rate of key processes will reach 50%; Compared to the level where the CNC rate of machine tools in manufacturing powerhouses is over 60% -70% internationally, there is still significant room for improvement in China's CNC rate of machine tools. So whether it is the need for updating and replacing existing machine tools or the demand for newly added CNC machine tools every year, cutting tools as consumables for machine tool processing will experience a considerable growth in consumer demand. China has a large number of CNC machine tools, with low-end machine tools (with poor rigidity and low linear speed) being the majority. Imported mid to high end products cannot achieve efficiency, and domestically produced blades have better adaptability. The mid to low end blades of Huarui and Oukeyi can meet the needs of domestically produced machine tools. 2.5. Positive 5: Hook up a resource rich country, international trend is emerging, and overseas markets are vast China is a major country in hook resources, accounting for 56% of global hook mineral reserves. According to data from the United States Geological Survey, the global hook ore reserves in 2020 were 3.4 million metric tons, of which China accounted for 56%, reaching 1.9 million metric tons. China's hook ore production is far ahead, with a production of 69000 tons in 2020, accounting for 82% of the global total production of 84000 tons. Broaden your horizons, domestic leader Meow is targeting the global market of 38 billion US dollars. From 2017 to 2020, the proportion of overseas revenue of Oukeyi and Huarui Precision showed an upward trend, indicating smooth expansion of overseas business. According to research data from OKE, the company has been laying out in overseas markets for many years, and has successfully entered some markets in Asia that do not have high-end tool production capacity, gaining full recognition. On the other hand, in the European and American markets in the rough machining field, the feedback on cost-effectiveness and usage value is satisfactory. 2.6 Market forecast for CNC cutting tools According to statistics from the China Machine Tool Industry Association, the production of metal cutting machine tools in China slowly declined after reaching 783000 units in 2016, and bottomed out after dropping to 416000 units in 2019. There has been a rebound and upward trend since 2020. It is known that the production of machine tools reached a historical peak from 2011 to 2014. According to data from the industrial control network, the update cycle of machine tools is estimated to be around 10 years. Old machine tool equipment will be replaced from 2021 to 2024, and demand will accelerate. Assuming that half of the machine tools produced ten years ago need to be replaced, the production of metal cutting machine tools in the Nth year from 2021 to 2025 is: production N=production N-10 * 0.5 * (1+m), m is a new increment, and m=0.25~0.45. Therefore, the expected production of metal cutting machine tools from 2021 to 2025 is 53/529/533/579/528000 units. The CNC rate of metal cutting machine tools in China reached 43.2% in 2020 and 45% in 2021. Assuming an annual growth of about 3%, the CNC rate will reach approximately 59% by 2025, corresponding to a production of approximately 311000 CNC machine tools. With the maturation of precision manufacturing technology, the quality and service life of machine tools are also improving, and their replacement cycle may be extended to 12-15 years. Based on a replacement cycle of 10-12 years, it is estimated that the number of metal cutting CNC machine tools will increase from approximately 2.167 million to 2.94 million in 2021-2025. According to statistics, the consumption of CNC blades in China was about 400 million in 2020. Assuming an average of 250 days of operation per year for each CNC machine tool, it can be concluded that each machine tool consumes 0.8 hard alloy blades per day. According to the prospectus of OKE, the tool market has been in short supply in the past two years, and the production capacity utilization rate of top enterprises has exceeded 100%; With the addition of manufacturing, the demand for precision machining is gradually increasing. We expect that from 2021 to 2025, based on the average daily consumption of 0.9 hard alloy blades per CNC machine and 250 working days per year, the demand for CNC blades in China will reach 660 million by 2025. 3.1 Domestic listed companies expanding production and summarizing production capacity In recent years, due to the sustained prosperity of the cutting tool industry, major manufacturers have formulated production capacity plans, constructed production lines for raw material bars and hard alloy blades, and actively expanded production 3.2 Prediction of future supply-demand matching situation According to data from the China Hook Industry Association, the consumption of CNC blades in China was about 240 million pieces in 2019. The annual production of the four leading cutting tools in the industry in 2019 was 41.94 million pieces from Ouke, 40.56 million pieces from Huarui Precision, and 64.4 million pieces from Zhuzhou Diamond. From this, it can be concluded that CR3 accounted for 61% of the total in 2019. Assuming that the production capacity utilization rate of the three top companies is 100% from 2021 to 2025, and the proportion of CR3 hard alloy blade production increases by 3% annually, it can be calculated based on the production capacity planning of the top three companies that the total industry production capacity from 2021 to 2025 will be 4.05/4.7/5.47/573/585 million pieces, respectively. Therefore, the production capacity gap in 2021 is about 136 million pieces, which will decrease to 60-70 million pieces by 2025. So as long as technology can break through, on the one hand, the stock market share of import substitution can digest the rapidly expanding production capacity of cutting tool companies. In addition, during the post epidemic period, domestic top companies are expanding overseas at an accelerated pace. On the other hand, the increase in domestic demand and exports are also sources of demand for digesting production capacity. 4.1. Competitive landscape of the cutting tool industry in the international market The Chinese hard alloy industry started relatively late, about 20 years later than the technological level of developed countries such as Europe and America. After more than 50 years of development, the Chinese hard alloy industry has continuously approached the international level through technology introduction and independent research and development, and the strength of domestic leading enterprises has gradually been able to compete directly with overseas leading enterprises. The competitive landscape of the cutting tool industry in the international market can be divided into three major camps based on technological strength and development stage. First camp: European and American tool manufacturers represented by Sandvik Group, Isca Group, Kenna Metal Group, etc., have the ability to provide turnkey engineering to customers and currently hold a leading position in the global industry. Both their strong technical strength and rich product series ensure their advantageous position; At the same time, these manufacturers generally have the characteristic of focusing on developing overall cutting machining solutions. In high-end application markets such as aerospace and military industry, the first tier enterprises have also opened up a significant gap with other enterprises. However, such enterprises also face the problems of long delivery cycles and high prices, with large and medium-sized enterprises and foreign-funded enterprises being the main users in the domestic market. The second camp: mainly composed of Japanese and Korean tool enterprises, such as Mitsubishi from Japan, Taikolo from Japan, Kyocera from Japan, Teguk from South Korea, etc. Among them, Japanese tools account for the largest proportion of imported tools in China. The market strategy of Japanese and Korean enterprises is different from that of European and American enterprises, mainly focusing on wholesale in large quantities. Therefore, products are very common in the domestic hardware wholesale market, with prices lower than European and American cutting tools and slightly higher than domestic cutting tools. The third camp: mainly domestic tool enterprises, with a large number of domestic enterprises and significant differences in level. Most enterprises mainly produce traditional tools, such as white steel knives (ordinary high-speed steel knives), welding knives, etc. Top companies include Zhuzhou Diamond, Xiamen Jinlu, OKE, and Huarui Precision, with products mainly targeting the mid to low-end cutting tool market. 4.2. The cutting tool industry has high barriers and is a capital and technology intensive industry Establishing a moat with funds and technology makes it difficult for the industry to enter. The design and preparation process of CNC blades involves four core technologies and is a technology intensive industry, so the entry threshold for the industry is relatively high. In addition, according to the response to the inquiry letter from Oukeyi's listing, CNC blades are also capital intensive products, as forming a complete production line for CNC blades requires equipment investment of at least 100 million yuan. 4.3. Domestic blades break through technological bottlenecks, and some products catch up with Japan and South Korea In terms of material and cutting performance, some domestically produced cutting tools have reached the same level as Japan and South Korea. Mitsubishi is an internationally renowned tool manufacturer, and VP15TF is a representative product of its stainless steel machining blades. Its performance can represent the second level of the tool industry; The comparison of the experimental results of OP1215, a similar product of OKE, shows that the performance indicators of OP1215 are on par with Mitsubishi's products. Coupled with the advantages of low prices of domestic cutting tools and local services, the prospect of further penetration into downstream manufacturers is promising. In terms of manufacturing technology, leading domestic manufacturers have also reached the industry's advanced level. The performance stability and accuracy consistency of CNC cutting tools are important references for measuring the level of technology, and their standards can be expressed by the carbon content (drilling magnetic value) in the hard alloy matrix. If the drilling magnetic fluctuation level of the same brand and different batches of blades is controlled at 0.1%, which is equivalent to a carbon content fluctuation of 0.01%, it means that the product performance is stable and consistent. According to the response to the inquiry letter regarding the listing of Oukeyi, the company's CNC blade accuracy can reach the G-level (0.025mm, known as high-precision level in the industry) and has good consistency through self-developed manufacturing processes. 5.1.1. Sandvik's industry leader relies on a complete product line A comprehensive product line is the guarantee for Sandvik to provide complete solutions. Sandvik's cutting tool business started early and established a leading position by expanding its product line through acquisitions. At present, Sandvik can provide product+service solutions, covering the entire industry chain of cutting tools upstream and downstream. Sandvik, with its technological advantages, holds a significant share in the global tool market, accounting for 13.3% of the global market in 2019 and 7.4% of the domestic market, mainly concentrated in the mid to high end tool field. Establishing a good cooperative relationship with software companies is the future development trend of tool enterprises. In 2021, Sandvik acquired CNC Software Inc. from the United States in order to promote digitalization and customized services. The company is a leading supplier of CAD/CAM (Computer Aided Manufacturing) software solutions for the manufacturing industry and a widely used manufacturer of Mastercam in the industry. By acquiring CNC Software, Sandvik acquired a world-class CAM brand with approximately 270000 users and a strong dealer network. 5.1.2. Sandvik - Analysis of Main Business Composition Looking at Sandvik's revenue structure in 2020, the manufacturing and processing solutions business of metal cutting tools accounted for 37.6% of the group's revenue of 32.8 billion Swedish kronor (equivalent to RMB 22.3 billion) in 2020. Divided by downstream industries, the mining industry accounted for 40% of Sandvik's 2020 revenue, followed by the machinery industry at 23%. By region, 54% of Sandvik's manufacturing and processing solutions business comes from Europe, with North America and Asia each accounting for about 21%. The business volume in South America, Africa, the Middle East, and Australia is relatively small. 5.2. The concentration of the cutting tool industry is expected to further increase There are numerous domestic cutting tool enterprises with small scale, and the industry concentration needs to be improved. According to data from the China Machine Tool and Tool Industry Association, there were a total of 715 measuring tools and instruments enterprises with sales exceeding 20 million yuan in 2019, and about 35 domestic enterprises established CNC blade production lines. Only 10 domestic enterprises produced over 1 million CNC blades in 2019, while only three domestic enterprises produced over 40 million CNC blades annually, namely Zhuzhou Diamond (80 million pieces), Ouke Yi (55 million pieces), and Zhuzhou Huarui (50 million pieces). Taking Sandvik as a lesson, broaden the category and strengthen the brand effect from products to services. Since its establishment, Sandvik has been committed to solving practical problems for customers, and its products have continuously innovated according to customer needs, gradually developing from hard alloy blades to nearly 100000 categories including coated blades and other special material blades; In addition to its products, Sandvik also offers tool consultation and customized services. High quality products combined with comprehensive services can broaden sales channels, expand customer base, and strengthen brand effect. Top domestic companies may also embark on the path of mergers and acquisitions, with the goal of expanding their product lines and providing customers with complete solutions. From hardware to software, from equipment support to technological reserves, China is expected to have an industry leader occupying most of the market in the future and gradually expanding overseas. 5.3. The quality requirements of users determine the future development direction of cutting tools Downstream customers have a low proportion of tool costs, are not sensitive to tool prices, and raw material price increases are easily transmitted. Looking at the proportion of tool costs to downstream customers surveyed three times, enterprises with tool costs accounting for less than 1% are showing a decreasing trend, from 22.5% in the second survey to 9.6% in the fourth survey; Enterprises with tool costs accounting for 2% to 3% have shown an upward trend, increasing year by year from 20.6% in 2002 to 31.2%. Overall, the proportion of tool costs is on the rise. Enterprises with tool costs accounting for 1% to 4% of total production costs have increased from 59.6% to 68.3%, while those with a 4% proportion are still relatively small. Therefore, downstream industries are not highly sensitive to tool price increases. The quality requirements of users for cutting tools determine the future development direction of cutting tools. When purchasing cutting tools, users consider many factors, among which the most important is cutting performance, followed by tool life, product price, delivery time, and brand. In addition, there are supply chain management, the ability to provide turnkey solutions, and pre-sales and after-sales services. 6.1 Profitability of Related Companies The enterprises that have received widespread attention in the cutting tool industry are as follows: CR4 (Zhonggou High tech, Xiamen Jinlu, Oukeyi, and Huarui Precision), Ganzhou Aoketai, a wholly-owned subsidiary of Zhangyuan Jinye, as well as Arno Precision, a subsidiary of Baoshi Co., Ltd., and Zhuzhou Kelite (which merged to establish Zhuzhou Kereno New Materials Co., Ltd.). 6.2. Comparison of business layout and development stages of top enterprises The development stages of top domestic enterprises vary, so their business layout is also different. 6.3 Zhonggou High tech (000657. SZ) - Zhuzhou Diamond Relying on the competitive advantage of the complete industrial chain, the company focuses on building an industrial system integrating mining, smelting and deep processing, building China's first and world-class hook industry group, and has the only State Key Laboratory of cemented carbide in the industry. We have the following subsidiaries: 1. Zhuzhuan Company, a leading comprehensive supplier of hard alloy cutting tools in China, is a pioneer in the industry and currently the only enterprise in China that can compete with Sandvik. It has strong technical strength, diversified product structure, 40000 to 50000 product categories, and the production capacity of CNC blade supporting overall cutting tools; 2. Zhugang Company, the cradle of China's hard alloy industry; 3. Jinzhou Company, the largest in China in the design and production of precision micro drills, cutting tools, and high-precision progressive molds for PCBs; 4. A leading company in the field of hook based hard surface materials in China; 5. Manage Nanhard Company, one of the largest hook smelting and powder product bases in China. 6.4. Oukeyi (688308. SH) The company was established in 1996, mainly engaged in the research and development, production, and sales of hard alloy products and CNC tool products. In the field of hard alloy products, the company's production of serrated blades ranks first among domestic peers; In the field of CNC tool products, there are nearly 10000 product categories, and the blade production capacity can reach 100 million pieces by 2022. In the segmented application fields of stainless steel and steel parts processing, some products can replace similar imported products. In 2020, the company achieved a revenue of 702 million yuan, a year-on-year increase of 16.7%; The net profit attributable to the parent company was 107 million yuan, a year-on-year increase of 20.6%. In 2020, hard alloy and CNC cutting tools achieved revenue of 397 million yuan and 303 million yuan, accounting for 56.6% and 43.2% respectively. The company adopts a business model mainly based on direct sales and supplemented by distribution. The direct sales model is divided into general direct sales (main model) and OEM/ODM (important supplementary) sales models; In the revenue of CNC tool business, the proportion of distribution revenue in H1 2020 was 54.6%. It is the third batch of small giant enterprises. 6.5 Huarui Precision (688059. SH) The company was established in 2007, focusing on the research and application of hard alloy CNC blades. It has independent core technologies in four major fields: matrix materials, groove structures, precision forming, and surface coating, and has developed three series of products: turning, iron cutting, and drilling. The core products of the company are at the forefront of domestic cutting performance in terms of machining accuracy, machining efficiency, and service life. Some products have reached international advanced levels and have entered the domestic high-end market dominated by European, American, Japanese, and Korean cutting tool enterprises for a long time. Especially, iron cutting blades have formed a significant competitive advantage. The company's revenue scale is steadily increasing, and its gross profit margin remains high. The company achieved a revenue of 312 million yuan in 2020, a year-on-year increase of 20.6%; The net profit attributable to the parent company was 89 million yuan, a year-on-year increase of 23.6%. Thanks to the four core technologies and the established advantages in research and development, production, equipment, channels, and market, the company's gross profit margin has remained around 50% in recent years, demonstrating excellent profitability. The company adopts a sales model dominated by distribution and supplemented by direct sales, with direct sales accounting for 31.4%. After years of production and operation accumulation, the company has established a complete distribution system, cooperating with over 100 distributors, focusing on major domestic CNC blade distribution centers such as South China, East China, and North China, covering more than 20 provinces and cities. In addition, the company has actively expanded its overseas markets and accelerated its global layout in recent years. |